How We Use Energy

Philadelphia Water Department activity accounts for approximately 34 percent of all greenhouse gas emissions created by the City of Philadelphia’s municipal buildings and operations.

Pumping drinking water across thousands of miles of pipes for consumption and treating wastewater are our most energy-intensive activities.

On average, we treat and distribute nearly 224 million gallons of drinking water to 1.6 million customers per day. Our wastewater and stormwater system collects and treats an average of 379 million gallons per day, serving 2.2 million people in the city and surrounding suburbs and protecting local waterways.

More than 50 percent of our energy needs are provided by purchased electricity, and 90 percent of that is used at wastewater treatment plants and drinking water pumping stations. Natural gas accounts for another quarter of the energy used.

Biogas created from anaerobic digestion of waste sludge at two of our wastewater treatment facilities is used for energy needs at treatment plants, including heating and electricity generation at our cogeneration facility, and comprises 15 percent of our overall energy usage. The remainder of our energy footprint comes from onsite generation projects and diesel and gasoline used in PWD fleet vehicles.

As participants in the Office of Sustainability Greenworks program, we are committed to reducing energy usage and carbon emissions by improving energy efficiency and utilizing renewable energy, including deriving energy from waste streams.

Resource Recovery

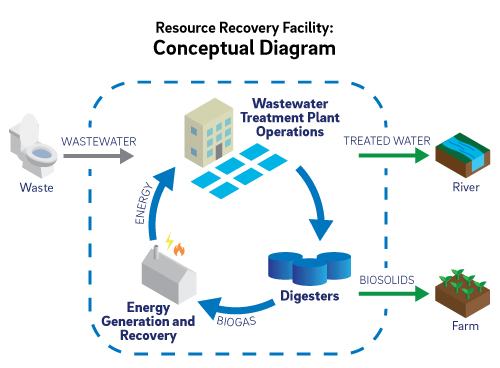

What you flush down the toilet might seem like pure waste, but it actually has the potential to produce energy. Resource recovery—capturing and reusing the nutrients, energy and water collected at wastewater treatment plants—is a major component of our strategy to reduce fossil fuel dependency.

Capturing and reusing biogas, a wastewater byproduct, for energy is a central focus of recovery efforts at the Philadelphia Water Department because this abundant resource can be used to replace the fossil fuels that cause climate change.

The Southwest and Northeast Water Pollution Control Plants use organic wastewater solids to produce this methane-rich biogas for heating buildings, plant processes, and energy generation. Learn more about biogas applications in wastewater treatment.

Annually, we use enough biogas collected from wastewater to offset 30,000 metric tons of carbon dioxide equivalent (mt CO2e) emissions—that’s equal to taking more than 6,400 passenger vehicles off the road for one year.

While the impact of that carbon offset is significant, we still burn, or flare, biogas not being used at the plants. Our goal is to find innovations that allow us to beneficially use all biogas produced at Water Pollution Control Plants.

Resource recovery investments at our facilities can help our city reduce emissions that cause climate change by reducing the amount of natural gas we purchase and use. Using fuel created at treatment plants makes our operations more self-sufficient and strengthens our resilience in response to extreme weather events, which are likely to increase in frequency and potentially be more severe due to climate change.

What We’re Doing Now

Northeast Water Pollution Control Plant Biogas Cogeneration Facility

The Northeast Plant began biogas cogeneration in 2013. Also known as Combined Heat and Power (CHP), the system captures both thermal and electrical energy from wastewater gas.

Anaerobic digesters process sludge filtered from wastewater to produce biogas, which is then fed to four internal combustion engines to create heat and power for the plant. In addition to providing a sustainable fuel source—the water that needs to be treated generates its own heat and power for treatment—creating on-site energy minimizes what would normally be lost in transmission, making the process even more efficient.

The energy created by Northeast WPCP biogas cogeneration provides the amount of electricity it would take to power approximately 3,650 homes. The system can provide up to 85 percent of the plant’s electricity needs and offsets over 20,000 mt CO2e annually, equivalent to the greenhouse gas emissions produced from using 2.2 million gallons of gasoline.

Southeast Water Pollution Control Plant Solar Array

The Southeast Water Pollution Control Plant’s solar array began operation in May 2011. Taking advantage of the abundant and sustainable energy provided by our sun, these solar panels generate electricity using photovoltaics, which are semiconductor, light-capturing materials that drive an electric current through an inverter or battery. The Southeast plant’s solar array includes more than 1,000 solar panels, which generate around 330,000 kWh of electricity—enough to power 35 Pennsylvania homes—each year, providing $30,000 in annual energy savings.

Biosolids Recycling Center

For decades PWD has been safely treating and processing biosolids, the residuals resulting from the wastewater treatment process, from our three Water Pollution Control Plans. Since 2012, biosolids have been thermally dried into environmentally beneficial, pathogen-free pellets used as organic fertilizer and renewable fuel. Biogas produced by the digesters aids the thermal drying and solids treatment process, reducing the amount of natural gas needed and further lowering emissions from burning fossil fuels. Prior to the thermal drying process, biosolids were composted, applied to farmland as fertilizer, or landfilled. Many trucks were required for the transport of this material. Currently operations are contained at the thermal drying facility, resulting in far less greenhouse gas emissions from truck traffic.

Aircraft Deicing Fluid at Southwest Water Pollution Control Plant

In the winter of 2008, we began accepting aircraft deicer from the Philadelphia International Airport to feed to our anaerobic digesters at the Southwest Water Pollution Control Plant. The addition of organic compounds found in deicing fluid has two benefits: it increases the production of the methane-rich biogas that we can use to decrease fossil fuel consumption, and it keeps the deicing fluid, toxic to both humans and animals, safely out of our waterways.

Climate Change Adaptation

In addition to addressing climate change by decreasing fossil fuel emissions and reducing energy use, the Philadelphia Water Department is planning for a future that is impacted by climate change through the Climate Change Adaptation Program (CCAP).

Read more about the program →

Greenhouse Gas Trends

PWD is a large user of energy and has a correspondingly large carbon footprint. As the City of Philadelphia pursues aggressive greenhouse gas reductions goals – 80% reductions by 2050– PWD will adopt a parallel approach. While maintaining and enhancing our core business, PWD will focus on energy reduction and the development of alternative energy generation, thereby lowering our carbon impact.

Since 2006, PWD has reduced GHG emissions by 12%. The use of renewable fuels and onsite electricity generation at our wastewater treatment plants as a positive impact on our greenhouse gas footprint.

More recently, power plants have been using natural gas in place of coal. The transition of electrical generation away from coal-fired power plants has reduced the carbon footprint of the entire regional electrical grid. Because of this, our emissions from purchased electricity have also declined. The City of Philadelphia is committed to cleaning the City’s energy supply and moving away from fossil fuel sources of electricity, thereby further transforming the regional electricity grid.

Our resource recovery projects reduce our dependence on purchased electricity, shrinking our greenhouse gas footprint even more. Energy efficiency gains through equipment upgrades and replacement will continue to mean less energy usage and less greenhouse gas emissions.