Download summaries of this SMP and its maintenance guidance, with quick reference information for clients and developers:

Cisterns SMP One-Sheet

Cisterns Maintenance Guidance One-Sheet

4.5.1 Cistern Introduction

Cisterns are storage tanks, located either above or below ground, that hold rainwater for beneficial reuse. Cisterns are multi-function systems that help to meet the Philadelphia Water Department (PWD) Stormwater Regulations (Stormwater Regulations) and collect water for reuse. Rainwater may be collected from rooftops or other impervious surfaces and conveyed to cisterns for storage. Stored water may drain by gravity or be pumped to its ultimate end use. This process, often referred to as rainwater harvesting, may include the use of captured water as permitted by local plumbing and building codes for:

- Exterior washing (e.g., car washes, building facades, sidewalks);

- Make-up water for mechanical systems (e.g., cooling towers, condensate make-up);

- Ornamental water fountains;

- Toilet and urinal flushing;

- Laundry; and/or

- Other uses, as approved.

Irrigation as a use for runoff stored in a cistern is not an acceptable strategy for meeting the Stormwater Regulations.

Quick Tip

Required cistern design and material standards are denoted in this Section by easy-to-reference numerals.

Sizing considerations for cisterns include both the frequency and volume of water usage demand, if applicable, and the frequency and volume of supply. Cisterns may also be sized to provide detention/flow control along with water conservation as a hybrid system.

Cisterns only provide an effective flow control function if the stored water is partially or fully used (or emptied) between storms. This function restores available storage volume within the cistern in advance of the next storm. For example, unless it is oversized, a fire storage system provides no meaningful stormwater benefit if it is fed by rainwater because fire storage systems must always be full, in case there is a fire.

Cisterns can be combined with other stormwater management practices (SMPs) in series to meet the Stormwater Regulations. The designer is referred to Section 3.2.3 for information on using SMPs in series.

The design recommendations within this Section are to serve as guidance only. Site-specific parameters, such as anticipated water demand, will dictate alternative designs and calculations which will be reviewed accordingly.

When Can Cisterns Be Used?

Cisterns can be used as part of a comprehensive stormwater compliance and reuse strategy for residential, commercial, and industrial areas. They are typically located within or adjacent to buildings. In addition to above-ground cisterns, rainwater harvesting systems can be sited beneath lawns, recreational areas, parking lots, and other hardscape surfaces, provided that overburden loads and utility conflicts are evaluated.

Key Advantages of Cisterns

- Can be used to provide rate control within small/constrained spaces

- Decrease demand on the municipal water supply and water costs for the end user, when used as part of a rainwater harvesting system in accordance with City, State, and Federal code restrictions

- Can be sited, through flexible design options, beneath lawns, recreational areas, parking lots, other impervious areas, or within buildings when space constraints exist

- Provide educational benefits, especially at public and/or highly visible sites

Key Limitations of Cisterns

- May not be able to fully meet the Water Quality requirement

- Limited to circumstances where there is a year-round water demand that can replenish storage capacity between storms

- May be subject to additional City, State, and Federal code restrictions

- Require draining before a freeze when located on the surface, to prevent structural damage

- Require strict adherence to regularly scheduled inspections because the maintenance needs are not easily visible

- Does not improve aesthetics or provide the ancillary environmental benefits associated with vegetated SMPs, such as habitat creation and improved air quality

Key Design Considerations for Cisterns

- The specific end use of harvested rainwater can influence other design considerations, including cistern location, type of treatment, and delivery and distribution, among others.

- If a cistern is used for rainwater harvesting, a distribution system is needed to deliver stored water to its ultimate end use. It is often best to locate a cistern close to the building or drainage area to limit the amount of pipe needed for delivery or distribution of water. Pumps can be used to convey stored rainwater to the end use. When the water is being routed from the cistern to the inside of a building for non-potable use, pumps can be used to feed a much smaller pressure tank inside the building, which then serves the internal water demands. Cisterns can also use gravity flow to accommodate indoor residential uses (e.g., laundry) that do not require high water pressure.

- Depending on the intended use for the captured water, the level of treatment can vary. For some non-potable uses, filtration can be limited to sediment removal. Other uses may require treatment to remove microorganisms via physical filtration and disinfection.

- Cisterns can be placed underground, indoors, adjacent to buildings, and on rooftops that are structurally designed to support the added weight. The designer can work with architects and landscape architects to strategically site the cisterns. If cisterns are sited near the ultimate end use, costly distribution systems can be minimized.

- Rainwater harvesting is most effective when the volume and frequency of rainfall and the size of the contributing drainage area can generate sufficient water for the ultimate end use. Rooftops are most often targeted for rainwater harvesting systems. Rainwater can also be harvested from other impervious surfaces, such as parking lots; however, this typically requires more extensive treatment prior to use. Water Quality compliance is largely a function of the type of material covering the drainage area.

- For any cistern that discharges onto an adjacent property, a drainage easement may be required and is recommended.

Cistern Types

Cisterns can be distinguished by their location and by the type of water use they support. With respect to location, cisterns can be categorized in two ways.

Surface tank systems can be sited on rooftops or integrated into commercial sites. They may drain by gravity or be pumped.

Subsurface tank systems are typically pumped. Because the cisterns are below the surface, they do not interfere with the landscape.

With respect to use of stored water, rainwater harvesting systems can be categorized in three ways.

Runoff can be captured and stored for outdoor use, including exterior washing and architectural water features. Irrigation as a use for runoff stored in a cistern is not an acceptable strategy for meeting the Stormwater Regulations.

Runoff can be captured and stored for indoor use if properly treated and managed. A non-potable rainwater harvesting system cannot be directly connected to the potable plumbing of a building. The non-potable plumbing needs to be kept separate and properly labeled. With more extensive treatment, rainwater may be used for drinking purposes. The designer should seek professional guidance on the rules governing non-public potable water.

When a specific use for harvested rainwater cannot be identified or when the supply of harvested rainwater significantly exceeds demand, then a hybrid system using both water conservation and a delayed discharge to a down-gradient pervious area or another SMP can be considered.

4.5.2 Cistern Components

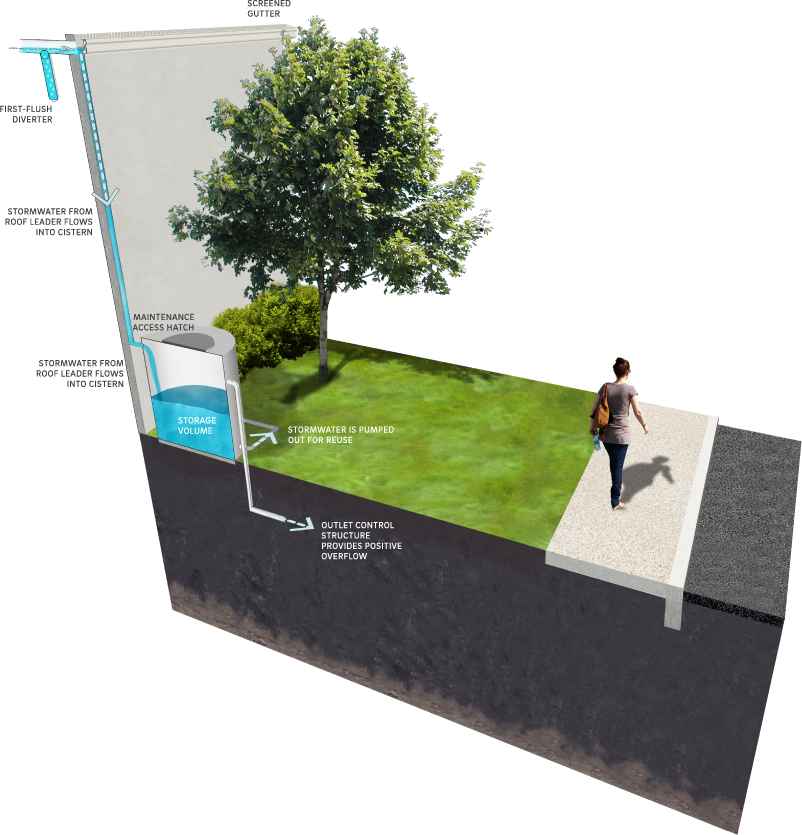

Figure 4.5‑1: Surface Cistern with Typical Features

Pretreatment Component

Pretreatment systems capture trash, sediment, and/or other pollutants from stormwater runoff before delivery to the storage area. Pretreatment needs will vary significantly depending on the contributing drainage area composition and use. Pretreatment can include structures such as sumped and trapped inlets, sediment/grit chambers, media filters, inlet inserts, or other appropriate prefabricated or proprietary designs to remove sediment, floatables, and/or hydrocarbons from stormwater runoff prior to being conveyed to a cistern. The designer is referred to Section 4.10, Pretreatment, for more information on pretreatment systems.

The following pretreatment options are often used with cisterns that manage roof runoff:

Gutter screening – All larger debris (e.g., leaves and twigs) must be screened at the gutter, roof, or at the edge of the impervious surface.

Prefiltration devices – Prefiltration devices prevent smaller particles from entering the cistern. The choice of the proper type of prefiltration device depends on cistern configuration and rainfall patterns.

- First flush diverters route the first flow, or flush, of water from the catchment surface away from the cistern prior to entry into the tank. While gutter screens are effective at removing larger debris such as leaves and twigs, first flush diverters can be used to remove smaller contaminants such as dust, pollen, bacteria from insect and animal droppings, and other harmful contaminants. Options for first flush can include a standpipe with slow drainage and a floating ball that seals off the top of the diverter pipe, among others.

- Roof washers are placed just ahead of cisterns and are used to filter small debris from harvested rainwater. Roof washers use a small tank, usually between 25 and 50 gallons in size, with leaf strainers and a filter with openings as small as 30 microns. The filter functions to remove very small particulate matter from harvested rainwater. All roof washers must be cleaned on a regular basis.

- Rainwater pre-filters screen rainwater before it enters the cistern on a continuous flow basis. These screens are preferable to first flush diverters and roof washers because they have significantly higher collection efficiencies.

The designer is referred to Section 4.10, Pretreatment, for more information on pretreatment systems.

Inlet Control Component

Inlet control systems convey and control the flow of stormwater from the contributing catchment area to a cistern. Inlet control needs will vary depending on the design of stormwater conveyance systems and the site layout. The designer is referred to Section 3.4.2 for guidance on stormwater conveyance system design. The designer is referred to Section 4.11, Inlet Controls, for more information on inlet controls.

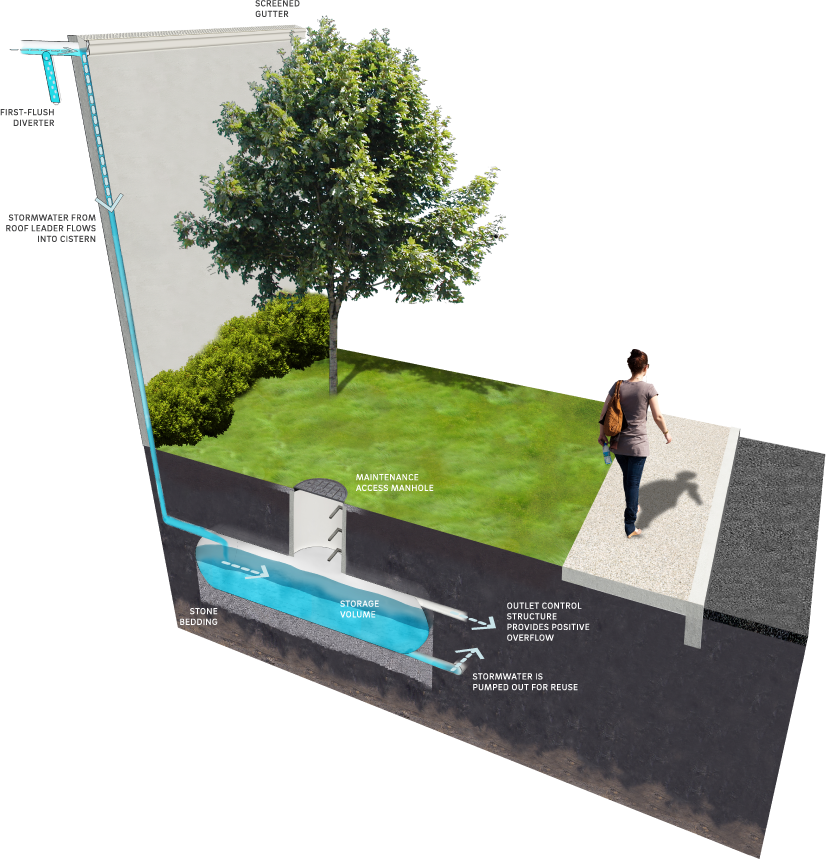

Storage Area Component

The storage component is the cistern, or tank, itself, which temporarily holds stormwater runoff before it can either be reused or be released downstream at a controlled rate, depending on the system design. Cistern capacities generally range from 50 to 50,000 gallons, but they can be as large as 100,000 gallons or more for larger projects. Multiple cisterns can be connected in series to balance water levels and to tailor to the storage volume needed.

Outlet Control Component

Outlet controls within a cistern control the amount of water that is stored for reuse and the rate at which the excess water is discharged from the cistern. These structures can provide a range of functions, including the following:

- Controlling how much water is stored for reuse;

- Meeting drain down time requirements;

- Controlling the rate of discharge from the SMP and limiting water surface elevations during various storm events; and/or

- Bypassing of flows from large storm events.

Outlet controls may include orifices and weirs. The designer is referred to Section 4.12, Outlet Controls, for more information on outlet controls.

Inspection and Maintenance Access Component

Safe and easy inspection and maintenance access to all major components within a cistern is critical to ensuring long-term performance. Inspection and maintenance access structures provide a portal to subsurface structures within a cistern. They most commonly consist of a panel, port, or manhole. Access points provide access to subsurface cisterns, both for inspections and routine maintenance, and for pumping water out of subsurface cisterns in cases of failure or severe damage. Manholes provide access for maintenance personnel and equipment to perform maintenance and inspections. Cleanouts provide access for hoses and vacuum equipment. Observation wells provide access to the bottom of subsurface cisterns for performance inspections and monitoring. Access structures may also serve additional functions, such as joining subsurface pipes. The design of water distribution systems, internal plumbing systems, and water treatment systems required for rainwater harvesting end uses is beyond the scope of this Manual.

Figure 4.5‑2: Subsurface Cistern with Typical Features

4.5.3 Cistern Design Standards

General Design Standards

- The maximum allowable drain down/withdrawal time for any portion of storage intended to meet the Water Quality requirement is 72 hours after the 24-hour storm event.

- Positive overflow must be provided for large storm events, up to and including the 100-year, 24-hour storm, or, if the project is exempt from Flood Control, the ten-year, 24-hour storm. Overflow structures and pipes must be designed to convey at least the ten-year, 24-hour storm.

- The minimum allowable freeboard above maximum ponding depth is four inches or the diameter of the outlet pipe, whichever is greater.

- The soil bearing capacity or foundation upon which the cistern will be placed must be considered, as full cisterns can be very heavy. This is particularly important for above-ground cisterns, as significant settling could cause the cistern to lean or be damaged.

- Designers must consult the City’s Building and Plumbing Codes (administered by the City of Philadelphia Department of Licenses and Inspections (L&I)) to determine the allowable indoor uses and pipe labeling and routing (i.e., separate stud bays), and State and Federal codes for required treatment and management of harvested rainwater.

- In cases where a municipal backup supply is used, rainwater harvesting systems must have backflow preventers or air gaps to keep non-potable harvested water separate from the potable water supply. Distribution and waste pipes, internal to the building, must be designated as such per the City’s Building and Plumbing Codes (administered by L&I).

Pretreatment Design Standards

- Pretreatment of runoff from all inlets is required to keep sediment, leaves, contaminants, and other debris from the system. The purpose of pretreatment is to maintain functionality and cleanliness of pumps and to significantly cut down on maintenance by preventing organic buildup in the cistern, thereby decreasing microbial food sources.

- Acceptable form(s) of pretreatment include, at a minimum, sumps and traps for inlets, sump boxes with traps downstream of trench drains, and filter strips for overland flow. The designer is referred to Section 4.10, Pretreatment, for more information on design standards for pretreatment systems.

- Screening:

- Gutters and downspouts must be fitted with leaf/debris screens along the entire length of the gutter leading to the cistern tank. Leaf/debris screens must be made from a corrosion-resistant material with screen openings in the range of 0.25 inches to 0.50 inches. Leaf screens must be inspected on a regular basis to prevent accumulated leaves and debris from clogging the gutter openings.

- All inlets and vents to a cistern must be protected by 1/6-inch stainless steel mesh screens, which keep insects, vermin, leaves and other debris from entering the cistern.

- First-Flush Diverter:

- Approximately one to two gallons of water per 100 square feet of roof collection surface must be diverted to the first-flush chamber instead of the cistern tank.

- Once the first-flush chamber is full, the remainder of the stormwater is directed to the cistern tank. A slow release control valve or drip system is typically included in the design to empty the first-flush chamber automatically in between storm events.

- The first-flush diverter system must include an accessible cleanout.

Inlet Control Design Standards

- The designer is referred to Section 4.11, Inlet Controls, for information on design standards for inlet control systems.

Storage Area Design Standards

- The storage area must provide adequate storage for the Water Quality Volume (WQv) between the overflow elevation and the controlling low flow orifice elevation. If the water reuse demand is less than the WQv, and only a portion of the WQv drains down or is withdrawn in 72 hours, only that portion of volume will be considered for compliance, and the remainder of the WQv must be managed by an additional SMP in series. The designer is referred to Section 3.2.3 for information on using SMPs in series. Any portion of the storage that will not drain down or be withdrawn within 72 hours must be excluded from the system’s storage volume estimation.

- When SMPs are used in series, the storage areas for all SMPs must provide cumulative static storage for the WQv, but there is no minimum storage requirement for each individual SMP used in series.

- Cisterns can be designed with additional storage beyond the WQv and with outlet controls that allow all remaining applicable Stormwater Regulations to be met.

- Opportunities and areas where water can be reused to meet indoor use needs must be identified. The rate at which water can be reused must be estimated. If the process of reuse is proposed to meet the Water Quality requirement, the WQv must be used in the first 72 hours after the storm event. Detailed calculations to demonstrate the anticipated daily, 72-hour, and monthly water use must be provided. For toilet use, volume must be calculated based on the number of flushes per day multiplied by gallons per flush.

- When cisterns are used to support on-site reuse, additional volume may be required (in addition to that required for Water Quality). A rough estimate may be obtained by performing a weekly water balance of rainfall and water reuse. Table 4.5‑1 below lists average monthly rainfall amounts at the Philadelphia International Airport. The difference on a weekly basis between rainfall depth and water depth needed must be estimated. This deficit must be multiplied by the roof drainage area to obtain an estimate of the cistern volume needed. The designer may choose to do more rigorous analysis using a long-term daily or hourly rainfall record, or a drier than average year.

Table 4.5‑1: Average Monthly Rainfall at the Philadelphia International Airport Table

| Month | Average Precipitation (inches) | Average Temperature (°F) High | Average Temperature (°F) Low | Potential Evaporation (inches per month) |

|---|---|---|---|---|

| January | 3.3 | 39.2 | 24.4 | 2.1 |

| February | 2.9 | 42.1 | 26.1 | 2.1 |

| March | 3.6 | 50.9 | 33.1 | 2.1 |

| April | 3.4 | 63 | 42.6 | 4.5 |

| May | 3.5 | 73.2 | 52.9 | 5.4 |

| June | 3.6 | 81.9 | 61.7 | 6.3 |

| July | 4.1 | 86.4 | 67.5 | 6.6 |

| August | 4.3 | 84.6 | 66.2 | 5.7 |

| September | 3.4 | 77.4 | 58.6 | 4.2 |

| October | 2.8 | 66.6 | 46.9 | 2.7 |

| November | 3.0 | 55 | 37.6 | 2.1 |

| December | 3.3 | 43.5 | 28.6 | 2.1 |

- Cisterns must be watertight and must be sealed using a water-safe, non-toxic substance.

- Bedding and Foundations:

- Cistern storage areas must be adequately bedded with stone to prevent settling or subsidence.

- Bedding thickness must vary according to system requirements, but must not be less than six inches.

- Over-excavation and replacement of loose or unstable subsurface material may be required if these conditions are encountered. A geotechnical engineer or other appropriate design professional must be consulted for additional guidance.

- Foundations/footers must be provided as warranted by system loading, geotechnical conditions, and manufacturer’s recommendations. Foundation designs must be performed by an appropriate design professional.

- The storage design must account for the potential loading from vehicles, as appropriate, based on expected maximum active loading, including consideration for emergency vehicles.

Outlet Control Design Standards

- Cisterns must provide for overflow or bypass of large storm events. The overflow from cisterns can occur through a hose, weir, pipe, or other mechanism. Overflow conveyance must have a capacity equal to or greater than the inflow pipe(s) and have a diameter and slope sufficient to drain the cistern while maintaining an adequate freeboard height. The overflow conveyance must be screened to prevent access to the cistern by small mammals and birds. The discharge from the overflow must be directed to an acceptable flow path that will not cause erosion. The outlet of the cistern to the pump is typically provided by a floating screened suction device on a hose.

- The designer is referred to Section 4.12, Outlet Controls, for additional information on design standards for outlet control systems.

Inspection and Maintenance Access Design Standards

- Cleanouts, manholes, access panels and other access features must be provided to allow unobstructed and safe access to SMPs for routine maintenance and inspection of inflow, outflow, underdrains, and storage systems.

- Access features for subsurface cisterns:

- Access features must be provided for all subsurface cisterns.

- A sufficient number of access points in the system must be provided to efficiently inspect and maintain the storage area.

- For cast-in-place vault systems, access features must consist of manholes or grated access panels or doors. Grated access panels are preferred to maintain airflow.

- For manufactured systems, the manufacturer’s recommendations must be followed.

- Ladder access is required for vaults greater than four feet in height.

- The access opening must be installed in such a way as to prevent surface or groundwater from entering through the top of any fittings, and it must be secured/locked to prevent unwanted entry.

4.5.4 Cistern Material Standards

Pretreatment Material Standards

- The designer is referred to Section 4.10, Pretreatment, for information on materials standards for pretreatment systems.

Inlet Control Material Standards

- The designer is referred to Section 4.11, Inlet Controls, for information on material standards for inlet control systems.

Storage Area Material Standards

- Cisterns may be constructed of fiberglass, concrete, plastic, brick, or other materials. Subsurface cisterns may be poured concrete or prefabricated plastic tanks similar to septic tanks. Pre-manufactured tanks should have a watertight rating as issued by the tank manufacturer. Non-galvanized steel, wood, or other products prone to environmental corrosion/decay are not approved for use. Other material types may be approved for use on a case-by-case basis.

- Proprietary products that store water in a variety of structures are also available. Some of these are designed to bear the weight of vehicles. With the addition of an impervious liner, many of the designs discussed in Section 4.4, Subsurface Infiltration, and Section 4.8, Subsurface Detention, can be modified to serve as reuse systems.

- Cisterns must be opaque or otherwise shielded to prevent the growth of algae.

Outlet Control Material Standards

- The designer is referred to Section 4.12, Outlet Controls, for information on material standards for outlet control systems.

Inspection and Maintenance Access Material Standards

- Cleanouts must be made of material with a smooth interior having a minimum inner diameter of four inches. The diameter of the cleanout must match the diameter of its connecting pipe up to eight inches. If the pipe is larger than eight inches in diameter, then the cleanout must be eight inches in diameter.

- The first-flush diverter system must include an accessible cleanout.

- Serviceways must consist of manhole openings with lockable manhole covers. Depending on the size of the cistern, multiple serviceway openings are recommended to support inspection, repair, and cleaning.

4.5.5 Cistern Construction Guidance

Proper construction of cisterns is essential to ensure long-term functionality and reduce long-term maintenance needs. A standard construction sequence for proper cistern system installation is provided below. This can be modified to reflect different cistern system applications or expected site conditions.

- Install temporary flow diversion.

- Install cistern as per manufacturer’s guidelines or design professional’s specifications. For subsurface cisterns, the designer is referred to Construction Guidance in Section 4.8, Subsurface Detention.

- Install downstream SMPs, if applicable.

- Install outlet control systems as per manufacturer’s guidelines or design professional’s specifications. The designer is referred to Section 4.12 for Outlet Controls construction guidance.

- Install pretreatment systems and inlet controls as per manufacturer’s guidelines or design professional’s specifications. Use temporary flow diversion or inlet protection to restrict runoff from unstabilized areas to reach the cistern. The designer is referred to Section 4.11 for Inlet Controls construction guidance.

- Once site is permanently stabilized, remove temporary flow diversion and/or erosion and sediment control measures to allow stormwater flow to the cistern.

4.5.6 Cistern Maintenance Guidance

Maintenance of cisterns focuses on the periodic removal of sediment and debris from pretreatment and storage areas. Sediment removal from tanks and pipes is typically conducted using vacuum or flushing systems. Guidance on the use and operation of vacuum or flushing sediment removal equipment is beyond the scope of this Manual; a maintenance professional should be contacted for additional details. As applicable, cistern maintenance procedures must meet Occupational Safety and Health Administration confined space entry requirements.

General recommended maintenance activities for cisterns are summarized in Table 4.5‑2.

Table 4.5‑2: Cistern Maintenance Guidelines

| Early Maintenance Activity | Frequency |

|---|---|

| Inspect inlet structures, outlet structures, and storage areas for trash and sediment accumulation. | Monthly for the first year after installation to determine ongoing maintenance frequency |

| Ongoing Maintenance Activity | Frequency |

|---|---|

| Regularly clean out gutters, gutter screening, first-flush chamber, and catch basins to reduce sediment load to the cistern. Clean intermediate sump boxes, replace filters, and otherwise clean pretreatment areas in directly connected systems. | As needed |

| Remove sediment and debris from cisterns according to the manufacturer’s recommendations or the site-specific maintenance plan. | As needed |

| Test sediment for toxicants in compliance with current disposal requirements if land uses in the catchment include commercial or industrial zones, or if indications of pollution are present. | As needed |

| Brush the inside surfaces and thoroughly disinfect. | Annually |

| Prior to freezing weather, to avoid structural damage perform winterization of cisterns as per manufacturer’s requirements or design professional’s specifications. | Annually |

| Inspect cistern and control structures. | Quarterly |

| Remove floating debris and accumulated petroleum products. | Quarterly |

| Maintain records of inspections and maintenance activity. | Ongoing |

Periodic inspections and maintenance of cisterns must be conducted by a qualified professional. Maintenance requirements for cisterns that are part of rainwater harvesting systems vary according to reuse. Detailed maintenance guidance for rainwater harvesting systems is beyond the scope of this Manual.

The designer is referred to Section 4.10, Pretreatment, Section 4.11, Inlet Controls, and Section 4.12, Outlet Controls, for information on maintenance guidance for pretreatment, inlet controls, and outlet controls.